Introduction to Spiral Conveyor Systems

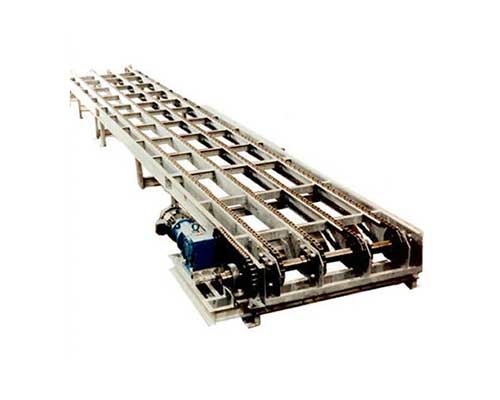

A Spiral Conveyor System is an advanced material handling solution that transports goods vertically while taking up minimal floor space. These systems are widely used in industries where space efficiency, reliability, and ease of operation are essential. By incorporating a helical or spiral design, these conveyors allow products to move upwards or downwards between levels, making them ideal for distribution centers, packaging facilities, warehouses, and production lines.

Perfection Engineering Corporation’s Spiral Conveyor Systems are designed to meet the demands of modern industries by providing a flexible and cost-effective solution to transport goods efficiently. With robust construction, precision engineering, and customization options, these conveyors enhance the overall productivity of operations.

Features of Perfection Engineering Corporation’s Spiral Conveyor Systems

Compact Design

One of the key advantages of a spiral conveyor is its compact footprint. The vertical spiral structure saves valuable floor space while allowing for the continuous movement of products between different levels. This makes it an excellent choice for facilities with limited space or where maximizing space is a priority.

Smooth and Continuous Flow

The spiral conveyor is designed to ensure a smooth and continuous flow of materials. Its spiral shape provides a consistent incline or decline, which prevents products from getting stuck or damaged. This feature is particularly valuable in high-speed operations where efficiency is crucial.

High Load Capacity

Perfection Engineering Corporation’s spiral conveyors are built to handle a wide range of load capacities. Whether you need to transport lightweight products like packaging materials or heavy items like industrial components, these systems can be customized to handle specific load requirements with ease.

Durability and Reliability

Durability is a hallmark of Perfection Engineering Corporation’s products. The spiral conveyors are made from high-quality materials, ensuring longevity and minimal maintenance. With a robust design and attention to detail, these conveyors can operate efficiently for extended periods, reducing downtime and maintenance costs.

Customizable Configurations

The company offers customizable configurations to meet the specific needs of different industries. Spiral conveyors can be tailored to accommodate varying belt widths, product sizes, and load capacities. Additionally, the spiral structure can be designed to suit specific space constraints and operational requirements.

Energy Efficient

Perfection Engineering Corporation’s spiral conveyors are designed with energy efficiency in mind. The system operates with minimal power consumption, which translates into reduced operational costs over time. This energy efficiency makes it an environmentally friendly solution for material handling.

Safety Features

Safety is a top priority for any industrial equipment, and spiral conveyors are no exception. These systems are equipped with safety features such as emergency stop buttons, protective guarding, and controlled speed adjustments to ensure the safe transport of products and protect workers from potential hazards.

Applications of Spiral Conveyor Systems

Spiral conveyors are used across a wide range of industries due to their versatility and efficiency. Some of the key industries that benefit from spiral conveyor systems include:

Food and Beverage Industry

Spiral conveyors are commonly used in the food and beverage industry for transporting products like packaged goods, bottles, cans, and other items. They are ideal for cooling, freezing, or storing food products at different levels in production facilities.

E-commerce and Warehousing

In the fast-paced world of e-commerce, efficient material handling is critical. Spiral conveyors are often used in fulfillment centers and warehouses to transport products between different floors, streamlining order processing and increasing efficiency.

Pharmaceutical Industry

The pharmaceutical industry relies on spiral conveyors for handling delicate products such as medications, vials, and medical supplies. These systems ensure a smooth and contamination-free movement of products.

Automotive Industry

In the automotive industry, spiral conveyors are used to transport components like tires, engines, and other heavy parts between assembly lines. Their high load capacity and durability make them ideal for handling automotive components.

Packaging Industry

Spiral conveyors are widely used in packaging facilities to move boxes, cartons, and packaged goods between different stages of the packaging process. They ensure a continuous flow of products and reduce manual handling.

Benefits of Using Spiral Conveyor Systems from Perfection Engineering Corporation

Space Efficiency

Spiral conveyors allow businesses to optimize their available floor space. Their vertical design means they take up less space than traditional conveyor systems, allowing businesses to make the most of their production or storage areas.

Increased Productivity

With the ability to transport goods between multiple levels in a continuous flow, spiral conveyors help streamline operations and reduce downtime. This results in faster processing times and increased overall productivity.

Reduced Labor Costs

Automating material handling tasks with a spiral conveyor reduces the need for manual labor, which in turn reduces labor costs. Workers can focus on more value-added tasks, while the conveyor system efficiently handles the movement of products.

Versatility

The customizable nature of Perfection Engineering Corporation’s spiral conveyors makes them suitable for a wide range of industries and applications. Whether it’s handling food products, industrial components, or packaging materials, these systems can be adapted to meet specific requirements.

Reliability and Durability

Investing in a high-quality spiral conveyor system ensures long-term reliability and minimal maintenance. Perfection Engineering Corporation’s commitment to quality means that their systems are built to last, providing a strong return on investment for businesses.

Safety and Ergonomics

The automated nature of spiral conveyors minimizes manual handling, reducing the risk of workplace injuries. Additionally, the controlled movement of products ensures a safe and ergonomic working environment for employees.